As an experienced manufacturer of fibre-reinforced plastics, we are proud to have been involved in the train toilet floor project for ICE 1 since 2019. This project was carried out as part of a redesign measure by the customer, Deutsche Bahn, and required a comprehensive overhaul of the train toilet floor to make it more resistant to the demands of daily use.

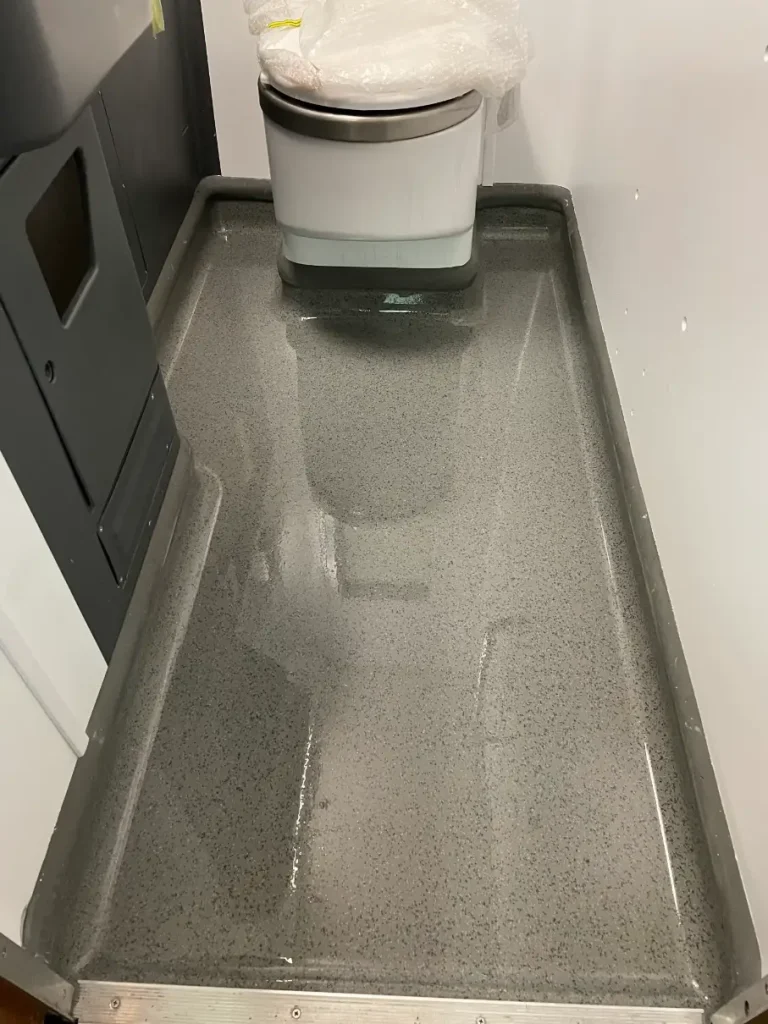

Our expertise in the production of fiber reinforced plastic materials was invaluable in the realization of this challenging project. The WC floor of ICE 1 has a foam core to increase durability, while at the same time the look of natural stone is achieved through the integration of quartz sand in the gel layer. This optic was very demanding in implementation, but thanks to our competence and experience we managed to meet the high demands of our client.

In addition, the WC floor has an extremely resistant protective coating that makes it resistant to scratches, cleaning agents, cigarette burns and other impacts on long-distance trains. This protective layer guarantees a long service life and increases safety and comfort for passengers.

We are proud to be part of this important project and contribute to the continuous improvement and development of public transport. We are convinced that our materials and expertise will continue to play an important role in designing modern public transport in the future.